Countries around the world have made an agreement to reduce GHG emissions in order to prevent global warming. In this agreement, the goal is to reduce GHG emissions without threatening food industry, in which achieving zero carbon emissions by 2050O is one of the main plans.

The highest amount of carbon emissions in the aluminum industry is related to electricity, power plants mainly use fossil fuels, which cause significant carbon emissions to the atmosphere. Rio Tinto’s aluminum sector released about 21.9Mt of carbon in 2021, down around 1% compared to the company’s greenhouse gas emissions in 2018. Alcoa’s carbon emission decreased by 23.9% in 2021 compared to 2015. Norsk Hydro recorded about 11.3Mt of carbon emissions in 2018.

Many countries decided to reduce GHG emissions through the Paris Agreement in 2015 with climate changes. The purpose of this agreement was to have a stronger response to the threat of climate changes. The long-term goal for temperature control in the Paris Agreement is to keep the growth of global average temperature to less than 2 degrees Celsius (3.6 degrees Fahrenheit) above pre-industrial levels, and limit it to 1.5 degrees Celsius (2.7 degrees Fahrenheit). This significantly reduces the effects of climate changes. Net emissions should be reduced as soon as possible and reach zero by the middle of the 21st century. To achieve a growth less than 1.5 degrees Celsius of global warming, GHG emissions must be declined by 50% by 2030. This is the sum of the nationally determined contribution for each country in the Paris Agreement. Another goal of this agreement is to better adapt to the adverse effects of climate changes and strengthen climate resilience and lower emissions of GHG in a way that does not threaten food industry. Moreover, the financial flow should be planned to reduce GHG emissions.

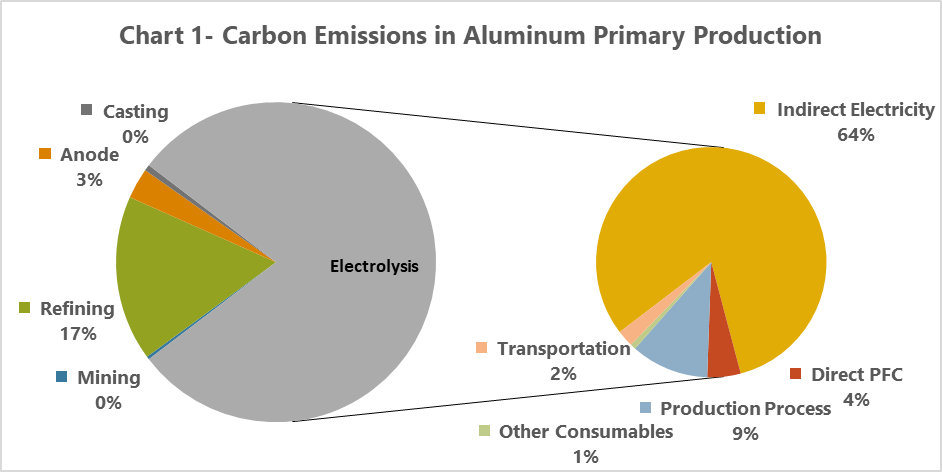

Aluminum industry is one of the main produces of a significant amount of GHG. The carbon emissions during the primary aluminum production process in 2018 is indicated in Figure 1. Besides that, a significant amount of electricity is consumed in the aluminum industry, and around 42.5% of the carbon dioxide gas released by the industry is from its electricity production site. The largest share in carbon emissions in aluminum production is allocated to the electrolysis process. The share of electricity consumed indirectly was about 64% of the carbon emissions of primary aluminum production in 2018.

Many aluminum producers have goals in line with the implementation of the Paris Agreement. Among these companies, Rio Tinto, Alcoa, and Norsk Hydro, which are the global largest producers, have plans to reduce GHG emissions.

Zero carbon emission by 2050

The aluminum melting process requires significant amounts of electricity and the use of carbon anodes leads to the GHG emission. Although most of Rio Tinto’s smelters are powered by renewable electricity, the Boyne and Tomago smelters in eastern Australia are mainly powered by coal-fired plants. Coal and natural gas used for heat and calcination are the two main sources of GHG emissions in the alumina refining process. The net emission of GHG from Rio Tinto’s aluminum sector was about 21.9Mt of carbon in 2021, which is around 1% less than in 2018. The effective measures in this reduction of carbon emissions are due to the improvement of processing efficiency, the use of electric boilers in alumina refining and the production cut in the Canada’s Kitimat smelter. Rio Tinto plans to spend about 1.3% of its revenue on reducing carbon emissions by 2030, based on Atubis estimates of the company’s revenue.

The intensity of GHG emissions in 2021 in Atlantic smelters using hydroelectric power was around 2.17t of CO2e per ton of aluminum. The carbon emission intensity of Rio Tinto’s Vaudreuil refinery is currently about 260kg of CO2e per ton of alumina.

In Australia’s Weipa, Rio Tinto will increase the solar power generation capacity of the local power grid more than triple by installing an additional 4MW of solar power and a 4MWh battery to advance decarbonization in the bauxite sector. Alcoa Company has set short-term and medium-term goals to reduce carbon emissions in line with the Paris Agreement. One of the company’s solutions in order to reduce carbon emissions is the use of renewable energy and the development of new technologies. One of Alcoa’s goals is to reduce GHG emissions by 30% by 2025 and 24% by 2030 compared to 2015. Now the company has achieved a 23.9% fall compared to the base level until 2021. The company plans to achieve net zero carbon emissions by 2050. The total equivalent emission of carbon dioxide (CO2e) was 21.8Mt in 2021, of which 17.4Mt are direct emissions. This shows a 9.1% drop in total carbon emissions and a 10.7% decrease in its intensity (the emissions volume per tonnes) compared to 2020. The downfall was primarily due to the downsizing of Intalco’s smelter and continued focus on sustainable operations and optimization. It should be mentioned that currently, Alcoa has 2 prominent brands with low carbon emissions for alumina and primary aluminum; Ecosource brand, which is related to alumina. Carbon emissions are less than 600kg/t of alumina, and the Ecolum brand of primary aluminum emits less than 4t of carbon dioxide equivalent to produce each tonnes of it.

Changing fossil boilers to electric

Norsk Hydro had around 11.3Mt of carbon emissions in 2018. The company has a plan to reduce carbon emissions by 1.1Mt by 2025. Norsk Hydro is trying to implement this program by changing the fuel of the boilers from fossil fuel to electric. The amount of GHG emissions from Alunorte fossil fuel power plant will be significantly reduced in 2030. The amount of GHG emissions will decrease to 7.9Mt from 2025 to 2030, which down about 30% of this volume compared to 2018. One of the company’s documented plans is the electrification of coal-fired boilers, improvement and optimization of the electricity network, and the smelting process from 2025 to 2030. With the electrification of the company’s boilers, Norsk Hydro’s carbon emissions will also be less than Alcoa’s EcoSource brand. The company’s other plans to reduce GHG emissions are using renewable energy, green hydrogen, and reduce emissions from smelters. The company has zero carbon emission in 2050 or earlier in its plan. Norsk Hydro uses hydroelectric power plants to produce aluminum, and to further reduce carbon emissions, it wants to use gas injection into the subsurface layers of the earth. In addition, this method is very expensive and nowadays, except for certain cases, it is not feasible. Also, Norsk Hydro Company intends to spend around 4.7% of its income for sustainable development based on Anubis analysis.