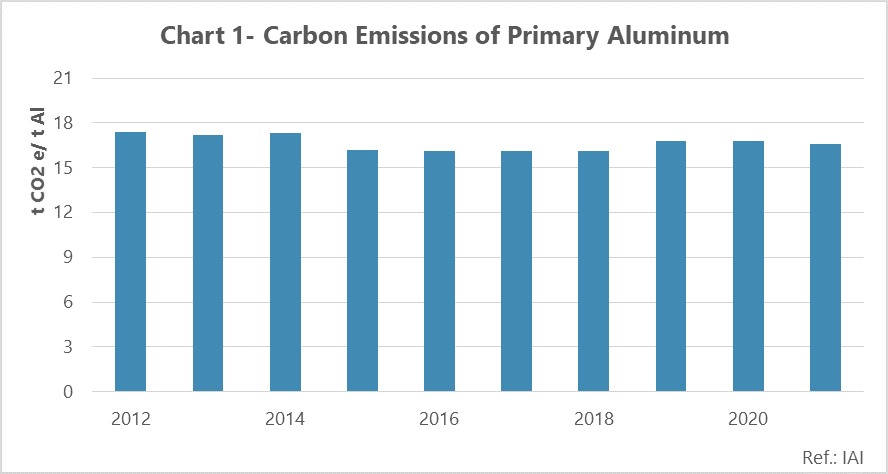

Carbon emissions per tonne of primary aluminum production have been decreasing from 2012 to 2021. After Paris Agreement in 2015, carbon emissions decreased by about 6.4% compared to last year. One of the reasons of this deduction in aluminum sector is the use of modern technology.

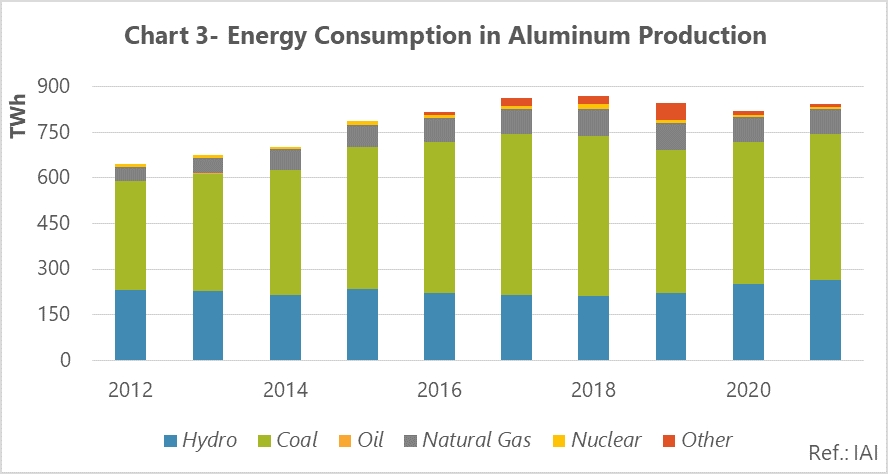

The largest share of carbon emission in the primary aluminum production process is allocated to electricity. The share of electricity in this process was about 64.5% in 2021. And the reason for this large share is used of sources like coal which emits significantly greenhouse gases.

Greenhouse gas (GHG) emissions from industries mainly come from burning fossil fuels for energy and some necessary chemical reaction to produce goods from raw material. In order to prevent the increase in world’s temperature, countries around the world made an agreement to reduce GHG emissions. The goal is to reduce the GHG without threatening food production. One of this Agreement’s aims is to achieve zero carbon emissions by 2050. Heavy industries which collectively produce more than 10 million tonnes GHG must be decarbonized to reach the goals of Paris Agreement.

One of the industries which emit much GHG is the aluminum industry. Regarding this fact that aluminum is a necessary material for some key industries such as manufacturing, transportation and energy transition. It’s expected until 2050 aluminum demand would increase by more than 50%. In addition to being an important raw material for a number of crucial transfer energy technology, aluminum is a significant source of CO2 emissions. Aluminum was responsible for about 3% of the world’s 9.4 giga tonnes of direct industrial CO2 emissions in 2021. A significant amount of electricity is consumed in aluminum industry and more than half of the carbon dioxide gas emitted by this industry comes from its electricity production site. One of these the most advanced technologies that nowadays aluminum producers studying on it, is inert anode process. This is a unique revolutionary process that could allow aluminum producers to completely stop using carbon anodes. The inert anode can be used potentially indefinitely but the most important thing is that what the inert anode-based reduction process emits into the atmosphere is not carbon dioxide but pure oxygen. An inert anode can produce as much oxygen as 70 hectares of forest.

Aluminum industry’s downward trend

Figure 1 indicates carbon emissions due to primary aluminum production from 2012 to 2021. Generally, from 2012 to 2021 carbon emissions has got downward trend. The carbon emissions’ compound annual growth rate (CAGR) driven by aluminum production during this time was about -0.5%. Atubis research shows that one of the reasons for this downward trend in this industry is expansion and employment of new technologies. Carbon emissions for primary alumina, production come from mining to extract bauxite, refining to produce aluminum, anode production electrolysis and casting. Most of this publication in aluminum industry is dedicated to electrolysis that had 77.4% on average share during the investigation time. In 2020 the carbon emissions amount for each tonnes of aluminum production was around 16.8 tonnes that with a 1.2% drop has reached 16.6 tonnes in 2021.

Figure 2 exhibits the carbon emissions of primary aluminum production by different sectors in 2021. Electricity consumption in aluminum industry has got share of 64.5% after that the second rank of carbon emissions in this industry is filled by thermal energy with 10.8%. Due to this fact that electricity is produced by using fossil fuels and the electricity consumption in aluminum industry is a high amount, electricity has got a significant share in carbon emission and the aluminum production’s share for carbon emission 10.2%. In aluminum production process from alumina, CO2 and CO emit from the reaction. The amount of energy consumption in aluminum production process from alumina was around 13.200 kWh while the whole energy consumption in aluminum production process was 14.100 kWh in 2021. The share of aluminum production from alumina in energy consumption than total energy consumption in production process is about 93.6%.

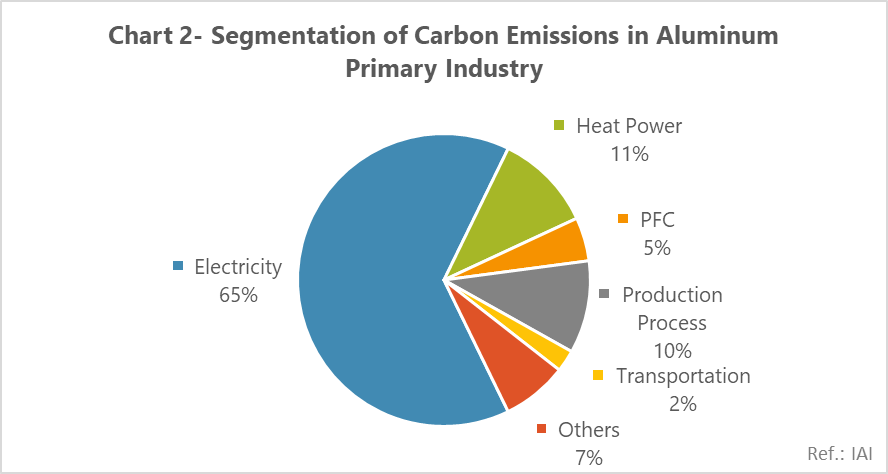

Figure 3 shows energy consumption in primary aluminum production by energy type in years 2012-2021. In general, the energy consumption trend in primary aluminum production from 2012 to 2018 had been increasing but since then, it’s become decreasing until 2021. According to Atubis evaluation and regard this growing trend in aluminum production during this time, the energy consumption has been rising despite the use of modern technology. As the other industries during the Covid-19 pandemic, aluminum industry encountered deduction in its production. This drop in the first quarter of 2021, reached 16 million tonnes which has got 2.2% deprecation in compared to the same period in 2019. In the beginning of the 2020, this pandemic made drop for this industry.

Figure 3 shows energy consumption in primary aluminum production by energy type in years 2012-2021. In general, the energy consumption trend in primary aluminum production from 2012 to 2018 had been increasing but since then, it’s become decreasing until 2021. According to Atubis evaluation and regard this growing trend in aluminum production during this time, the energy consumption has been rising despite the use of modern technology. As the other industries during the Covid-19 pandemic, aluminum industry encountered deduction in its production. This drop in the first quarter of 2021, reached 16 million tonnes which has got 2.2% deprecation in compared to the same period in 2019. In the beginning of the 2020, this pandemic made drop for this industry.

Since 2012 to 2021, the coal was the first source for getting needed energy in aluminum production. The coal’s share in primary aluminum production in 2021 was about 56.9% that was the largest share among the different energy sources. The share of coal in this production since 2012 to 2021 has been faced 14.2% increase. The second source which is used for making energy was hydroelectricity source and its share in 2021 was 31.3%. The amount of energy supplied from renewable sources was about 240.000gigawatt in 2012 and increased to around 281.000gigawatt in 2021.

Regarding Paris Agreement’s members’ attempts to carbon emission decrease, it’s expected this trend turned into a downward trend with technological development and extensive use of inert anode in the aluminum industry in the future. Also, the amount of carbon emissions would significantly decrease if instead of using nonrenewable energy, use renewable energy to produce electricity in the aluminum industry.